A Guide to Barcode Inventory Management Systems

A barcode inventory management system is more than a technological upgrade; it's a strategic shift in how you manage your business's most critical asset. It is an ecosystem of hardware and software designed to track products in real-time using barcodes, from receiving to fulfillment.

This system replaces inefficient spreadsheets or pen-and-paper methods. Instead of relying on manual counts prone to human error, you gain the ability to perform fast, accurate scans that provide a clear, live view of stock levels, locations, and movement across your entire operation. This foundational accuracy is what protects profit margins and drives revenue.

From Manual Chaos To Digital Clarity

Running a modern ecommerce store with manual inventory tracking is a recipe for operational disaster. The process is slow, riddled with costly mistakes, and impossible to scale. This chaos leads directly to stockouts, overselling, disappointed customers, and significant lost revenue.

A barcode inventory management system brings order to that chaos. In this system, barcodes serve as unique digital fingerprints for every item. Scanners become instant data capture tools, and your inventory software acts as the central brain, creating a single source of truth for your business. The result is instant visibility and control, which directly impacts your bottom line.

The Foundation Of Modern Commerce

The technology powering today's hyper-efficient supply chains began with a simple moment. On June 26, 1974, a pack of Wrigley's chewing gum became the first item ever scanned with a Universal Product Code (UPC).

That single scan launched a technology that now boasts an incredible 99.9% accuracy rate. For a Shopify merchant, this level of precision is transformative. It's the key to avoiding the costly nightmares of stockouts and overstocking—silent profit killers that erode margins. In an industry where the average cart abandonment rate hovers around 70%, ensuring product availability is paramount to capturing the slim 2.5% of visitors who convert.

Manual vs Barcode Inventory Management At a Glance

The transition from manual tracking to a barcode system represents a significant operational leap. It’s not merely about efficiency; it’s about fundamentally changing how you see and manage your most important asset: inventory.

| Attribute | Manual Inventory Management | Barcode Inventory Management |

|---|---|---|

| Data Entry | Pen, paper, or spreadsheets; slow and error-prone | Instant scans with handheld devices; fast and highly accurate |

| Accuracy | High risk of human error (e.g., typos, missed counts) | Near-perfect accuracy (99.9%), eliminating data entry mistakes |

| Speed & Efficiency | Labor-intensive and time-consuming for all tasks | Drastically reduces time for receiving, picking, and cycle counts |

| Real-Time Visibility | Data is always outdated; lag between counts and updates | Instantaneous updates provide a live, accurate view of stock |

| Scalability | Becomes unmanageable as order volume and SKUs grow | Easily scales with business growth without adding proportional labor |

| Labor Costs | Requires significant staff hours for counting and reconciling | Frees up staff to focus on high-value tasks instead of manual entry |

This is more than a minor upgrade. It is a strategic shift that enables a more resilient, scalable, and profitable business.

Beyond The Scan: A Strategic Business Advantage

At its core, a barcode system isn’t just about counting inventory—it's about making smarter business decisions that protect profit and drive growth. The reliable, real-time data it generates is the fuel for managing cash flow, forecasting demand, and protecting your margins.

By automating data capture, a barcode inventory system eliminates the costly human errors that erode profitability. It provides the foundational accuracy needed for everything from efficient order fulfillment to strategic financial planning.

This system transforms inventory from a passive asset into an active, data-rich resource that informs every part of your strategy.

The need for precise tracking is universal. In high-value industries, for example, meticulous tracking is non-negotiable to prevent loss and verify authenticity. You can see these principles in action by exploring how robust jewelry inventory management systems function.

For any growing Shopify brand, adopting this technology is a critical step toward operational maturity. It’s the backbone that supports a seamless customer experience and a healthy bottom line, making it essential for any modern ecommerce business looking to win.

The Three Pillars of a Barcode Inventory System

Every effective barcode inventory system is built on three core components working in perfect harmony. Think of it as a three-legged stool—if one leg is unstable, the entire structure fails. Understanding how these pillars support one another is key to seeing how this technology transforms a warehouse full of products into actionable business intelligence.

This setup isn't about small tweaks; it’s about replacing guesswork and tedious manual entry with speed and precision. The goal is to establish a single, reliable source of truth for your entire operation.

Pillar 1 Barcodes: The Digital Fingerprints

The first pillar is the barcode itself. Think of these as unique digital fingerprints for every physical item in your inventory. They are the language the system speaks, translating a physical object into a piece of data that can be read and understood in a fraction of a second.

Barcodes come in two main types, each serving a specific purpose:

- 1D (One-Dimensional) Barcodes: These are the classic striped barcodes you see everywhere, such as the UPC (Universal Product Code) on a retail product. They are excellent for storing basic information like a product SKU. Holding about 20-25 characters, they are hyper-efficient for straightforward product identification.

- 2D (Two-Dimensional) Barcodes: Think QR (Quick Response) codes. As a more advanced format, they store information both horizontally and vertically, allowing them to hold significantly more data—up to 2,509 numeric characters. This extra capacity allows you to embed richer details like batch numbers, expiration dates, or even a direct link to a product's page on your Shopify store.

This first pillar is about assigning a unique identity to everything, from individual items to the warehouse bins where they are stored. It's the foundational step that makes accurate tracking possible.

Pillar 2 Hardware: The Scanners and Printers

The second pillar is the physical hardware—the tools that interact with your barcodes. This is the bridge connecting your physical stock to your digital records, consisting primarily of barcode scanners and printers.

Scanners are the "eyes" of the system, reading barcodes and transmitting the data. The right scanner depends on your operational scale. A small business might use a simple USB scanner at a packing station. A busy warehouse, however, requires wireless mobile scanners or rugged handheld computers, giving teams the freedom to scan items during receiving, picking, or cycle counts anywhere on the floor.

Printers are equally crucial. They allow you to create new barcode labels on demand for unlabeled products, custom kits, or warehouse shelving. A reliable printer ensures that your digital fingerprints are clear, durable, and easily scannable, preventing frustrating misreads that can halt your workflow.

Pillar 3 Software: The Central Brain

The third—and arguably most important—pillar is the inventory management software. This is the command center, the brain of the operation that processes every scan and makes sense of all the incoming data. When a scanner reads a barcode, it's the software that performs the heavy lifting.

The software is where data becomes intelligence. It doesn't just record a scan; it updates stock levels across all channels, tracks item movement history, and generates the vital reports needed for accurate forecasting and purchasing.

This central hub connects your inventory data to the rest of your business. For any Shopify merchant, this is non-negotiable. A high-quality software solution will sync seamlessly with your store, ensuring the stock levels on your product pages perfectly mirror what’s actually on your shelves. This is especially critical for Shopify Plus merchants managing high-volume, multi-channel operations.

This real-time accuracy prevents overselling during flash sales and protects your brand's reputation. This final pillar turns a simple scan into a powerful, revenue-protecting action.

How a Barcode System Actually Changes Your Day-to-Day

Understanding the components of a barcode system is one thing, but its true value is revealed in how it overhauls daily workflows. This is not a minor upgrade; it's a fundamental shift from chaotic, error-prone tasks to smooth, predictable operations.

Let’s examine the "before and after" of three critical warehouse functions.

From Manual Check-In to Instant Receiving

Before Barcodes: A new shipment arrives, creating an instant bottleneck. An employee uses a clipboard and packing slip to manually check off items. They might miscount a box, misread a product name, or make a typo entering the data into a spreadsheet later. This process is slow, and inventory data isn't updated for hours or even a full day. This dangerous lag means you could easily sell stock you haven't officially received.

After Barcodes: The same shipment arrives. An employee uses a handheld scanner to zap the barcode on the master carton, instantly verifying the delivery against the purchase order. As products are unboxed, each item is scanned. Instantly, the system updates your stock levels in real-time. What used to take an hour of tedious labor is now completed in minutes with 99.9% accuracy. Your Shopify store reflects the new inventory the moment it's on the shelf, ready to sell.

Actionable Takeaway: Implement a "scan on receipt" policy immediately. Train your receiving team to scan every item against the purchase order before it's put away. This single step closes the gap between physical and digital inventory.

The End of Guesswork in Order Picking

Before Barcodes: An order is received. A picker gets a printed list and begins searching the warehouse for a "blue t-shirt, size medium." Among similar-looking products, it’s easy to grab the wrong size or color. These seemingly small mistakes are incredibly expensive, leading to costly returns, negative customer reviews, and the operational headache of processing the incorrect item back into stock.

After Barcodes: The process is now guided and error-proof. The picker’s mobile scanner displays the order and directs them to the exact bin location. They scan the bin's barcode to confirm they're in the right spot, then scan the product's barcode to verify the item. The system prevents them from proceeding if there’s a mismatch, eliminating picking errors before they happen.

This scan-based verification turns every step of the picking process into a checkpoint for accuracy. It's the operational foundation that ensures the right product gets to the right customer, every single time, protecting both your profit margins and brand reputation.

This level of precision is essential for a smooth operation. To see how these steps fit into the bigger picture, explore this complete guide to ecommerce order fulfillment.

Replacing Dreaded Audits with Simple Cycle Counts

Before Barcodes: The annual physical inventory count is an event most business owners dread. Operations shut down for a day or more while the entire team counts every item by hand. It’s a massive disruption, prone to counting errors, and the final numbers are already slightly outdated by the time you're done.

After Barcodes: The dreaded annual count is replaced by simple, ongoing cycle counts. Instead of counting everything at once, an employee can be assigned to count a specific section of the warehouse each day. Using a scanner, they can quickly and accurately count items in a few aisles. The process is fast, non-disruptive, and keeps inventory data accurate year-round.

- Benefit 1: Accuracy. Frequent, smaller counts catch discrepancies early, before they become major problems.

- Benefit 2: Efficiency. There’s no need for costly operational shutdowns. Business continues as usual.

- Benefit 3: Agility. Your team can run targeted counts on high-value or fast-moving items more frequently, focusing effort where it matters most.

By transforming these core daily tasks, a barcode inventory system does more than save time. It builds a foundation of accuracy and reliability that strengthens the entire business, from financial forecasts to customer satisfaction.

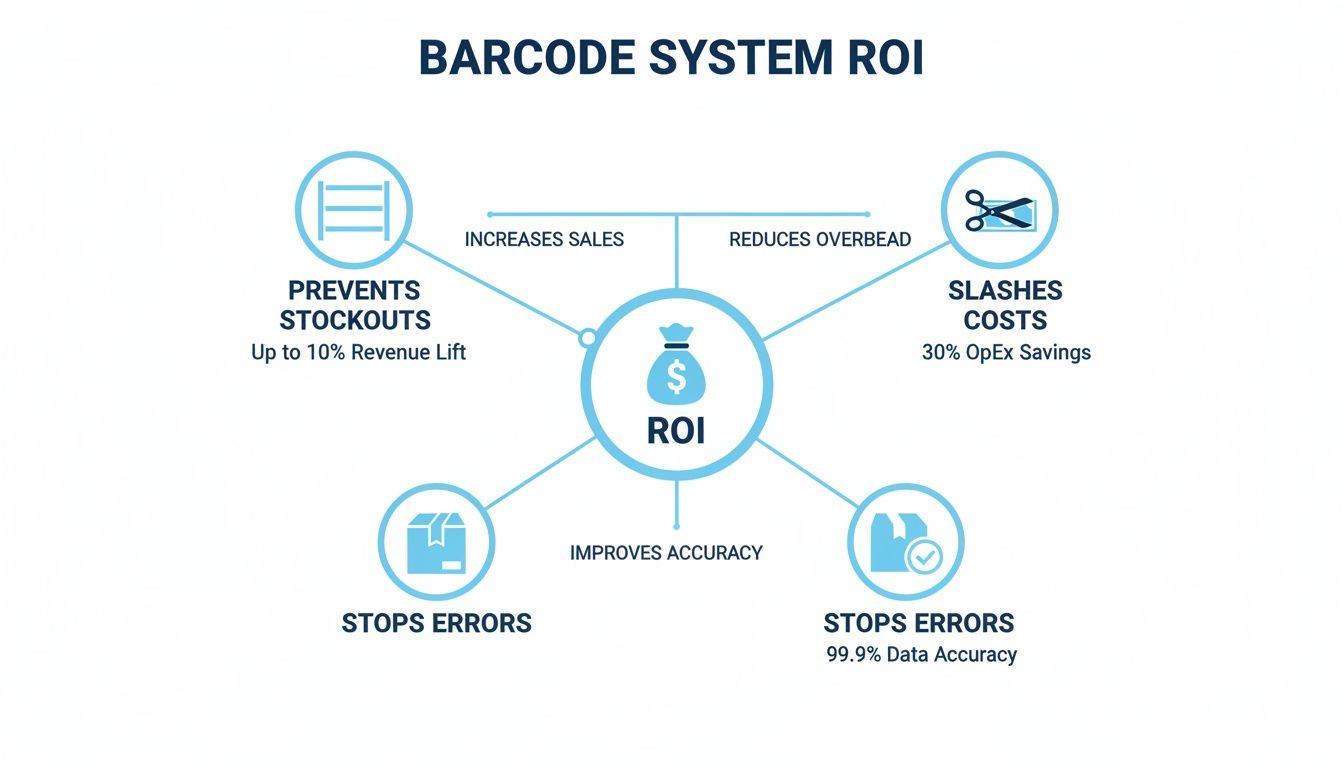

The Real ROI of a Barcode Inventory Management System

Implementing a barcode system is not an expense; it is a direct, measurable investment in the profitability and health of your business. The return on this investment extends far beyond efficiency—it closes financial leaks and provides the data-driven clarity needed to protect your margins and scale revenue.

The ROI becomes clear when you analyze the hard numbers. A significant portion comes from replacing manual, error-prone tasks with streamlined, automated workflows. This mirrors the financial gains seen when evaluating the true cost difference between manual and automated processes in other critical areas of ecommerce.

Slashing the Two Biggest Margin Killers

For most ecommerce brands, profit margins are silently eroded by two major inventory challenges: overstocking and stockouts. A barcode system is your frontline defense against both.

- Preventing Overstocking: Instead of tying up cash in slow-moving products, real-time data allows you to make purchasing decisions based on actual sales velocity. This frees up capital to invest in high-performing products.

- Eliminating Costly Stockouts: Every "out of stock" notice is a lost sale and potentially a lost customer. A barcode system provides the visibility to set intelligent reorder points, ensuring you never miss a revenue opportunity due to poor inventory planning.

By creating a single, undisputed source of truth for your inventory, a barcode system lets you walk that fine line of keeping optimal stock levels. This directly protects your cash flow and squeezes every last drop of revenue potential out of your catalog.

Recovering Hidden Labor Costs

Manual inventory management is a massive time sink. Think of the hours spent manually counting shipments, double-checking pick lists, or conducting all-hands physical inventory counts.

A barcode system returns those hours to your business. Scanning a pallet of new inventory takes minutes, not hours. Order picking becomes a guided, nearly error-proof process. Cycle counting becomes a simple, routine task instead of a warehouse-wide shutdown. This reclaimed time allows your team to focus on value-added activities that grow the business, such as quality control, customer service improvements, and operational optimization.

Eradicating Expensive Shipping Errors

A single shipping mistake triggers a costly chain reaction that directly impacts your profits. You absorb the cost of return shipping, the replacement item, and the labor to process the entire exchange.

Barcode-driven workflows in your picking and packing process virtually eliminate these blunders. By requiring an employee to scan an item to verify it against an order, you ensure the right product goes into the right box, every time. This not only saves money but also protects your brand's reputation by delivering a flawless customer experience.

To build the business case for this investment, consider the key metrics that typically see a major boost after implementing a barcode system.

Key Metrics Improved by Barcode Inventory Systems

| Metric | Typical Improvement Range | Business Impact |

|---|---|---|

| Inventory Accuracy | 99%+ | Drastically reduces stockouts and overstocking, leading to higher sales and better cash flow. |

| Order Picking Accuracy | Up to 99.9% | Slashes shipping errors, cutting costs from returns and improving customer satisfaction. |

| Labor Efficiency | 20-30% | Reduces time spent on manual tasks, allowing staff to focus on more valuable activities. |

| Order Fulfillment Speed | 25-40% Faster | Gets orders to customers quicker, boosting loyalty and enabling more competitive shipping offers. |

| Receiving Time | Reduced by up to 50% | Gets new inventory onto shelves and available for sale in half the time. |

These numbers demonstrate a clear connection: better data and automation lead directly to a stronger bottom line. Improving accuracy is a critical step in boosting overall business health. A key part of that is mastering operational efficiency, which you can explore further by learning to master your inventory turnover rate calculation.

Ultimately, the ROI isn't just about cost savings—it's about building a scalable, profitable operation that fosters customer loyalty.

Integrating Your System With Shopify and Marketing

A barcode inventory system does more than optimize your warehouse; it transforms raw inventory data into a powerful engine for growth. For Shopify merchants, this is where operational excellence meets marketing brilliance.

When you connect your inventory system directly to your Shopify store, your online storefront becomes a perfect, real-time mirror of what’s physically on your shelves. This sync is the foundation of a seamless customer experience. It prevents overselling during high-traffic events like flash sales, saving you from lost revenue and reputational damage.

The image below illustrates the financial upside of achieving this level of accuracy.

As you can see, the payoff comes from preventing stockouts, reducing labor costs, and eliminating expensive shipping mistakes—all powered by real-time, trustworthy data.

Turning Inventory Data Into Marketing Fuel

The true power of this integration extends beyond preventing stockouts. Precise, live inventory data fuels sophisticated marketing campaigns that connect with customers on a psychological level. When your marketing tools—like Klaviyo or popular SMS platforms—are aware of exact stock counts, they can operate with an authenticity that cannot be faked.

For example, connecting your inventory system to an email platform like Klaviyo unlocks powerful automation. When a popular item sells out, the moment a new shipment is scanned into your system, an automated "back in stock" email can be sent to every person who signed up for an alert. This immediacy capitalizes on peak customer desire, converting pent-up demand into instant sales. To learn more, explore our guide on building effective back in stock marketing campaigns.

The Psychology of Data-Driven Urgency

This is where you graduate from basic tactics to sophisticated psychological strategies. While generic countdown timers attempt to create urgency, savvy shoppers can spot manufactured pressure. Real urgency is rooted in truth.

Behavioral economics shows that perceived scarcity is a powerful motivator. When customers believe an item is genuinely in short supply, it triggers a fear of missing out (FOMO) and accelerates their decision to purchase.

This is where a platform like Quikly, an expert in the science of urgency marketing, steps in. It uses your live inventory data to create campaigns based on real scarcity, moving beyond the limitations of basic timer apps. Instead of a generic timer, you can build promotions on facts your customers can trust.

- Limited Quantity Offers: Launch a promotion like "Only 25 left at this price!" where the number is pulled directly from your actual stock levels. It’s not a gimmick; it's transparent and credible.

- Tiered Promotions: Offer a special discount to the first 100 buyers of a restocked product. Your system knows exactly when that threshold is met, creating a fair and exciting race.

- Low Stock Alerts: Automatically trigger a "Selling Fast!" banner on product pages when an SKU's inventory drops below 20 units.

This contrasts sharply with simple pop-up apps focused solely on email capture. By connecting real-time data from your barcode system to an advanced marketing platform, you create authentic "Moments" that are psychologically powerful because they are based on reality. This elevates your marketing from manipulation to genuine, data-driven persuasion, boosting both conversions and revenue without eroding customer trust.

Common Questions About Barcode Inventory Systems

Adopting a barcode inventory system is a significant step, and it's natural to have questions about the practical implications, including costs, technology, and team adoption.

Let’s address these common questions to provide the clarity and confidence needed to move forward.

How Much Does a Barcode System Cost to Implement?

There is no single price tag for a barcode system; the investment depends on the size and complexity of your operation. It's a spectrum of solutions designed to fit businesses of all sizes.

For a small Shopify store, the setup can be quite lean:

- A simple USB scanner can be found for around $50.

- Free barcode generation apps are available within the Shopify ecosystem.

- Your current inventory software or a basic, low-cost subscription may suffice.

As a business grows, its needs become more complex. A medium-sized brand might invest in more powerful hardware, like mobile scanners ranging from $300 to $1,000 each. This is typically paired with a dedicated inventory management software subscription, which can range from $50 to $500 per month.

For large-scale operations, particularly those on Shopify Plus, the investment can be substantial, often involving a full Warehouse Management System (WMS) and deeply integrated hardware. The key is to view this not as a cost but as an investment. The savings from reduced errors and faster fulfillment quickly deliver a clear ROI.

Can I Use Existing UPCs or Do I Need New Barcodes?

This is a frequent question with a simple answer: yes, you can and should use existing Universal Product Codes (UPCs) if your products already have them. It is the most efficient way to get started.

Any good inventory management software will allow you to scan these pre-existing UPCs and link them to the correct product in your digital catalog. You only need to create and print new, internal barcodes in specific situations, such as:

- For products that arrive from a supplier without any barcode.

- For custom kits or bundles assembled in-house.

- To label warehouse shelves, bins, or pallet locations for streamlined picking.

A flexible system should seamlessly handle both manufacturer barcodes and your own internal ones.

What Is the Difference Between a Barcode System and RFID?

The primary difference between these two technologies comes down to cost and the need for a direct line of sight. A barcode inventory management system uses optical scanners to read printed labels, meaning the scanner must physically "see" the barcode to capture the data. It is a proven, accurate, and cost-effective method for most businesses.

RFID (Radio-Frequency Identification), on the other hand, uses radio waves to read data from electronic tags. This technology does not require a direct line of sight, allowing you to scan dozens or even hundreds of items at once just by being in proximity.

While the speed of RFID is beneficial for tasks like receiving massive shipments, the technology is significantly more expensive. Both the individual tags and the reader hardware are more costly than their barcode counterparts. For the vast majority of ecommerce stores and retailers, a barcode system provides the ideal balance of accuracy, efficiency, and affordability.

How Do I Ensure My Team Successfully Adopts the System?

A new tool is only as effective as the people using it. Successful team adoption comes down to three key elements: clear communication, comprehensive training, and demonstrating the direct benefits to their daily work.

Actionable Takeaway: Start with training sessions that explain not just how to use the technology but why the change is being made. Show your team how it will eliminate frustrating picking errors and tedious manual counts. Create simple, visual Standard Operating Procedures (SOPs) for key tasks like receiving, picking, and cycle counting.

Most importantly, involve your team in the process early. Solicit their feedback on different software or scanners to make them champions of the change rather than resistant to it. Finally, celebrate small victories—like a week with zero shipping errors or a perfect cycle count—to build momentum and demonstrate the system's value.

A robust barcode inventory management system is the foundation for operational excellence. But to truly maximize its value, you must connect that data to your marketing strategy. Quikly bridges this gap, transforming your real-time stock levels into psychologically powerful, data-driven urgency campaigns that drive revenue and protect your brand's integrity. Learn how to turn your inventory data into your most effective marketing tool at https://hello.quikly.com.

The Quikly Content Team brings together urgency marketing experts, consumer psychologists, and data analysts who've helped power promotional campaigns since 2012. Drawing from our platform's 70M+ consumer interactions and thousands of successful campaigns, we share evidence-based insights that help brands create promotions that convert.